Analysis of the importance of formation, capacity separation and testing in the production process of 3C lithium batteries

- Share

- From

- Carol

- publisher

- Carol

- Issue Time

- Sep 22,2020

Summary

Analysis of the importance of formation, capacity separation and testing in the production process of 3C lithium batteries

Analysis of the importance of formation, capacity separation and testing in the production process of 3C lithium batteries

【Summary】:

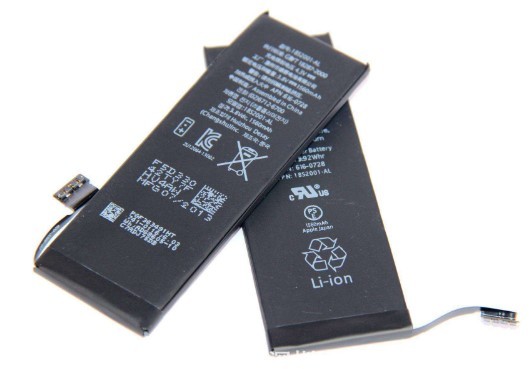

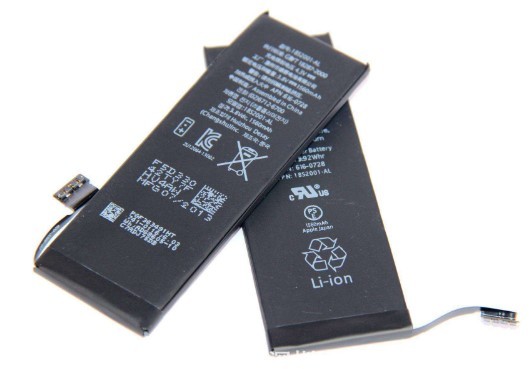

The performance of 3C lithium battery is closely related to the manufacturing process. The manufacturing process of 3C lithium battery is divided into four procedures, one is pole piece production, the other is battery cell assembly, the third is battery activation detection, and the fourth is battery packaging. The pole piece production is the basis of the 3C lithium battery production process, and the battery cell assembly is related to the performance of the 3C lithium battery and is the core process. The cell activation includes the formation, capacity division and testing of the battery. It is a key process after the production of 3C lithium batteries and before packaging and shipment. The battery packaging process is the last step in the production of 3C lithium batteries and is related to the quality of the finished battery. . In the production of 3C lithium batteries, every step directly affects the quality and safety of the battery. Therefore, every detail needs to be strictly controlled to ensure the safe and high-quality production of 3C lithium batteries.

The process flow of 3C lithium battery can be divided into positive electrode slurrying, negative electrode slurrying, positive electrode sheet, negative electrode sheet, steel shell assembly, liquid injection, testing, packaging, etc. In the second half of the process, the formation and capacity division of 3C lithium batteries are related to whether indicators such as cell consistency and yield can meet the requirements, which are an important part of cell activation detection. Why should 3C lithium batteries be formed and separated? Because after the production of the battery's single cells is completed, due to the constraints of the battery production process, the consistency of the parameters in terms of capacity, voltage, current, internal resistance, etc. is not high, so it is necessary to form and divide the battery to maintain the 3C lithium battery Consistency of batteries. The formation of 3C lithium batteries means that after the battery is manufactured, the positive and negative materials inside the cell are activated by charging and discharging to improve the battery's self-discharge, charge-discharge performance and storage performance. Capacity classification refers to the classification of battery capacity by testing battery capacity and other electrical performance parameters after the battery is manufactured. The formation and capacity division of 3C lithium batteries are completed by automated systems.

After the 3C lithium battery is formed and divided, it needs to be tested for its performance. In the test, the shrapnel micro-needle module can be used as a current transmission medium to stabilize the connection. The performance test of 3C lithium battery includes basic performance, safety performance, environmental performance and electrochemical performance. The shrapnel microneedle module can pass current in the range of 1-50A in the test, with strong overcurrent capability and an average of 20W The long service life can effectively improve the test efficiency of 3C lithium battery, and ensure the efficient and safe test. After passing the test, the 3C lithium battery is equivalent to the completion of the basic manufacturing process, and the battery packaging process is missing. The storage performance of 3C lithium battery is an important parameter to measure whether the overall performance of the battery is stable. Therefore, it is best to store the 3C lithium battery package for a period of time before shipment to allow the electrochemical performance of the internal components of the battery to stabilize. After a period of storage, the capacity and internal resistance of the 3C lithium battery will have a certain degree of change, so that you can better understand the self-discharge performance of the battery and ensure the quality of the 3C lithium battery.